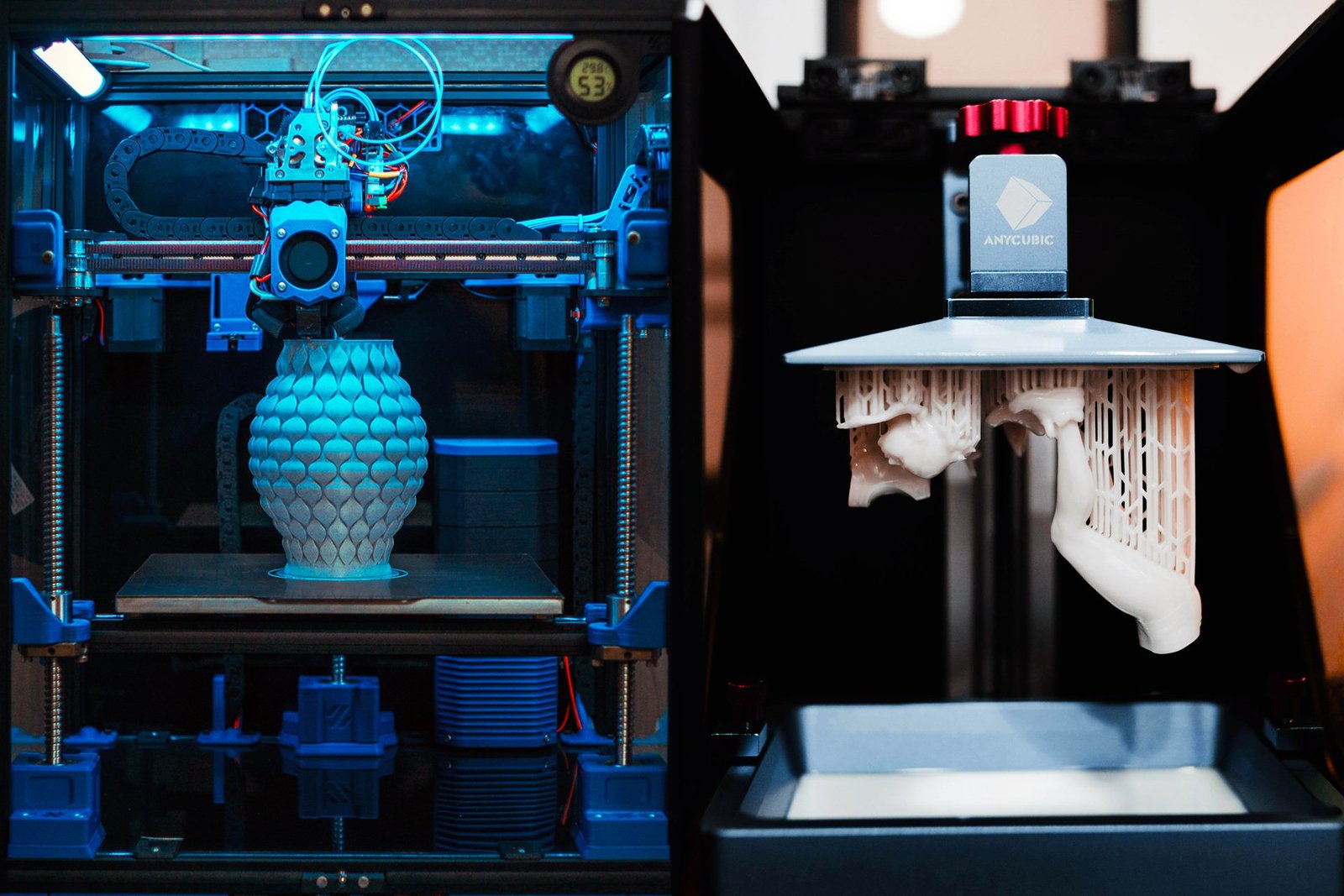

Once a niche prototyping tool, 3D printing now reshapes industries—manufacturing, medicine, art, and beyond—offering precision and flexibility once thought impossible. Each printing technique operates differently, with distinct mechanics driving its strengths and trade-offs. Navigating these options can be daunting; this guide unpacks the core methods, spotlighting how they work and where they excel to help you choose wisely. Curious about the materials behind them? Our materials guide dives into plastics, resins, powders, and more.

Overview of 3D Printing Techniques

These methods define how objects take shape—whether through molten extrusion, laser curing, or powder fusion. Their processes dictate resolution, speed, and complexity, from budget-friendly builds to industrial feats. Here’s the rundown.

Exploring Techniques by Method

Each technique brings a unique approach, detailed with technical insights and practical applications.

» Fused Deposition Modeling (FDM)

- Process: A heated nozzle extrudes thermoplastic filament, depositing it in precise 0.1–0.3 mm layers onto a build platform. The material cools and hardens instantly, stacking upward to form the object.

- Advantages: Low-cost printers and straightforward operation make it a go-to for beginners. Its versatility shines with widely available filaments.

- Limitations: Lower resolution leaves visible layer lines, often requiring post-processing. Overhangs demand support structures, slowing prints and adding waste.

- Applications: Rapid prototypes, educational models, custom home goods, DIY creations.

» Stereolithography (SLA)

- Process: A UV laser traces each layer’s outline across a vat of liquid resin, curing it into a solid at 0.025–0.1 mm precision. The platform lifts incrementally, building upward as excess resin drains away.

- Advantages: Exceptional detail and silky-smooth finishes set it apart for intricate work.

- Limitations: Higher equipment costs and mandatory post-processing—rinsing and curing—add steps. Resin brittleness can limit durability.

- Applications: Jewelry design, dental molds, detailed prototypes, miniature models.

» Selective Laser Sintering (SLS)

- Process: A high-powered laser fuses powdered material (typically 0.1–0.15 mm layers) in a heated chamber. Unfused powder supports the structure, eliminating the need for additional scaffolding.

- Advantages: Robust parts and complex, support-free designs make it a powerhouse for functional builds.

- Limitations: Expensive machinery and a grainy finish that may need sanding restrict it to pro settings.

- Applications: Functional prototypes, end-use parts, intricate aerospace and automotive components.

» Material Jetting

- Process: Nozzles jet photopolymer droplets onto a platform, curing them instantly with UV light in ultra-fine 0.016–0.032 mm layers. Dissolvable supports allow multi-material or color prints in one pass.

- Advantages: Unmatched resolution and vibrant, multi-texture outputs excel for visual models.

- Limitations: Weak mechanical strength and costly high-end systems narrow its scope.

- Applications: Full-color prototypes, medical visualizations, artistic multi-material pieces.

» Direct Energy Deposition (DED)

- Process: A focused energy source (laser or arc) melts metal wire or powder as it’s deposited, building in 0.5–2 mm layers. Often paired with argon shielding, it’s ideal for large-scale or additive repairs.

- Advantages: Strong, repairable outputs and the ability to enhance existing parts stand out.

- Limitations: Coarse resolution sacrifices detail, and complex setups drive up costs.

- Applications: Metal fabrication, turbine repairs, heavy machinery upgrades.

Applications Across Fields

FDM churns out quick mockups for engineers and hobbyists. SLA crafts delicate jewelry and dental tools with finesse. SLS powers durable aerospace parts and bold sculptures. Material Jetting dazzles with colorful demos, while DED fortifies industrial gear. Each method carves its niche, shaped by its mechanics.

Choosing the Right Technique

- Budget: FDM leads for affordability; SLA and SLS demand more upfront investment.

- Quality: SLA and Material Jetting top detail; SLS and DED prioritize function.

- Speed: Material Jetting and SLS move fast; DED lags for precision builds.

- Purpose: Prototyping leans toward FDM or SLA; end-use parts favor SLS or DED.

Summary Table

| Method | Resolution | Speed | Cost | Strengths | Limitations | Applications |

| FDM | 0.1–0.3 mm | Medium | Low | Affordable, easy | Layer lines, supports | Prototypes, home goods |

| SLA | 0.025–0.1 mm | Medium | Medium | Fine detail, smooth | Post-processing, brittle | Jewelry, miniatures |

| SLS | 0.1–0.15 mm | Medium–High | High | Strong, complex | Costly, grainy | Parts, prototypes |

| Material Jetting | 0.016–0.032 mm | High | High | Colorful, precise | Weak, expensive | Visual models, art |

| DED | 0.5–2 mm | Low–Medium | High | Durable, repairable | Coarse, complex | Repairs, fabrication |

Future of 3D Printing

The horizon glows with promise—AI-optimized designs, bioprinting breakthroughs, and construction-scale printers are emerging. Pair these with sustainable materials like recycled filaments, and 3D printing’s reach—from aerospace to healthcare—only deepens.